Streamline Order Fulfillment with the Pick List Screen in WMS

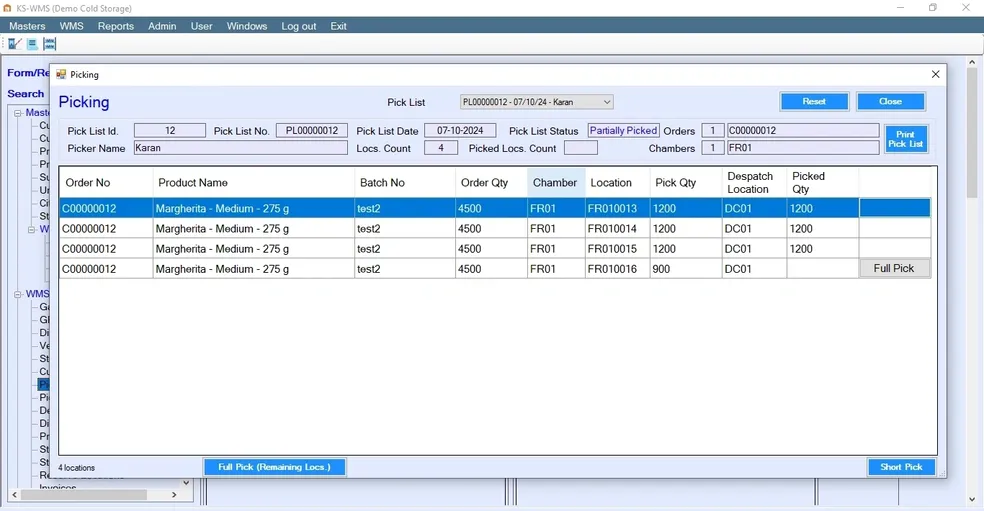

Efficient order fulfillment is crucial for any warehouse operation, and the WMS "Pick List" screen is designed to streamline this process. This feature offers a comprehensive solution for managing delivery orders, allocating stock, and optimizing picker assignments.

Users can select the delivery date, and the system automatically fetches all orders scheduled for that date. It allocates locations for picking based on Batch Number or stock out methods like FIFO (First In, First Out), FEFO (First Expiry, First Out), and LIFO (Last In, First Out). Users can then select available pickers, and the system divides the locations among them, optimizing the workload distribution.

Automating order fetching and location allocation reduces manual errors and speeds up order preparation. By dividing picking tasks among workers based on real-time data, the system maximizes productivity and minimizes unnecessary walking or waiting times. Supporting multiple stock out methods helps maintain optimal inventory levels and reduce wastage.

To use the "Pick List" screen, choose the delivery date for order preparation. The system will display all relevant orders in an easy-to-read list. It then determines the best locations for picking stock based on your chosen method, maintaining inventory accuracy. After selecting the available pickers, the system divides the locations among them, ensuring an efficient picking process.

Explore the capabilities of the "Pick List" screen and transform your warehouse operations with WMS. Stay ahead of the competition with timely deliveries and optimal stock management.